Out on the East Field track, three small vehicles commanded the attention of a growing audience. Friends and classmates surrounded each one as teams and drivers went over final preparations and checks. Soon, the crowds parted, a green flag waved through the air, and the silent vehicles pressed forward. The Electric Vehicle Race had begun!

As the capstone project for Machine Design II (ME 413), the Electric Vehicle Race put the skills of engineering students to the test. When designing the vehicles, they had to meet all guidelines in the Electrathon America Handbook. Some of the limitations included allowing only 73 lbs. for Sealed Lead Acid or AGM (Absorptive Glass Mat) batteries, including at least two safety switches that the driver or an observer can access, and requiring the driver to weigh at least 180 lbs. The race winner is determined by the most laps taken around East Field’s quarter-mile track in one hour without recharging vehicle batteries. The current record is 82 laps, set by Luke Shadrick’s (Engineering: Mechanical ’19) Team Mu in 2018.

“The vehicles have all been completely designed by each team and are built from raw materials and basic components,” said Mr. Michael Motz, an engineering and computer science faculty member who instructs the lab portion of the class. “The design of the cars is started in the fall in ME 412 (Machine Design I) with the construction happening in the spring with ME 413. Students learn the complete design process, including the initial planning, prototyping, and testing. The final test for the vehicles is the race day.”

Caleb Hamilton (Sr., PA) led Team Upsilon, who presented a blue and green painted cycle-car at the race. “My biggest takeaway from leading this project was to allow the members on my team to work what they know, and to be willing to assist them when they need help or direction,” he said. “If I had tried to micromanage every aspect of this project, I would’ve been way over my head in frustration and stress.”

Anna Schultz (Jr., IL) designed the internal frame for Team Upsilon’s cycle-car. “I designed the vehicle to be as safe as possible for the driver,” she said. “The entire class is very challenging, but the lab is the fun part. I got to work with some great people and use power tools I have never used before. I enjoyed getting to know my class better, and we all helped each other. There was cross-team assistance as well as great friendships and bonding times among the entire class.”

“A number of students have never worked in a shop environment with a wide variety of metalworking tools before, so the biggest increase has been in their ability to get desired results from the tools as the semester progresses,” said Mr. Motz. “The students learn about teamwork and complex mechanical design. Complex mechanical design comes from the many different parts working together in the design along with the need to consider both technical and non-technical limitations,” such as budgeting and scheduling.

Before coming to Pensacola Christian College, Hunter Alexander (Jr., GA) had already built and raced several electric vehicles through the Technology Student Association and Electrathon America. “When I found out that this was a junior project through the mechanical engineering program, it added to my interest in a degree at PCC,” he said. His team chose their vehicle type together. “We voted, and the design that won was a special tricycle design with the single front wheel being driven and steered. This design was the most power efficient, however the most complicated. We were in for a big challenge.”

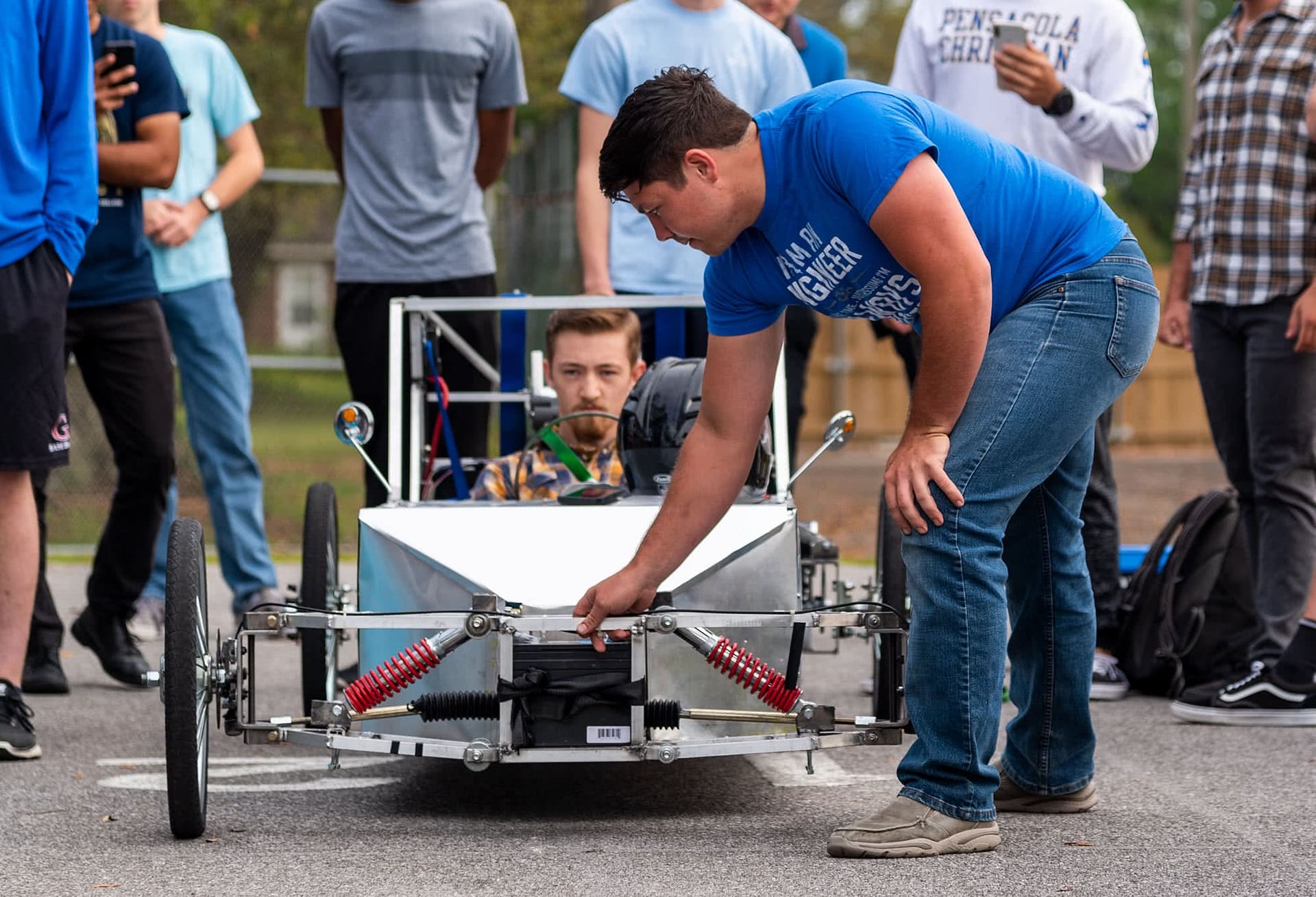

The race itself brought its own challenges to the competitors. Team Phi’s silver tricycle had a strong start but could not withstand the turns, running into a fence after 15 laps. The quick-acting team ensured the driver was okay and managed to keep the vehicle on the track a little longer, finishing with 21.5 laps total and 80 percent battery remaining. Team Upsilon’s cycle-car proved to be quick on turns but slower on the stretches in between. Although the car overtook Team Chi’s 4-wheel at one point, it ended up getting sidelined after the motor overheated and finished with 41.5 laps total. Team Chi, led by Joseph Lemon (Sr., AK), presented a silver box-shaped 4-wheel vehicle with red coils on the shocks. Their vehicle had the most consistent performance. While slower on turns, it was able to steadily continue the race over the hour, switching off one of the vehicle motors to conserve power, and finished with 64.5 laps total.

While winning can add to the experience, it wasn’t the focus of the two-semester project. These students went from lectures to labs and experienced the organized teamwork needed to build a working electric vehicle. “Many graduates have enjoyed their experience from the class. It has been one of the highlights of the mechanical concentration in the engineering program the past few years,” said Mr. Motz. “There is nothing quite like seeing the excitement of someone who thought a task was impossible discovering that there is a good way to get that task done well with much less effort needed.”

“I was able to learn so much about transmissions, gears, sprockets, and how everything tied together while building a car!” said Timothy Little (Sr., OK), who worked on the transmission for Team Upsilon’s cycle-car. “This project was for sure a challenge, but it was extremely rewarding to see our cars racing in their completed state!”