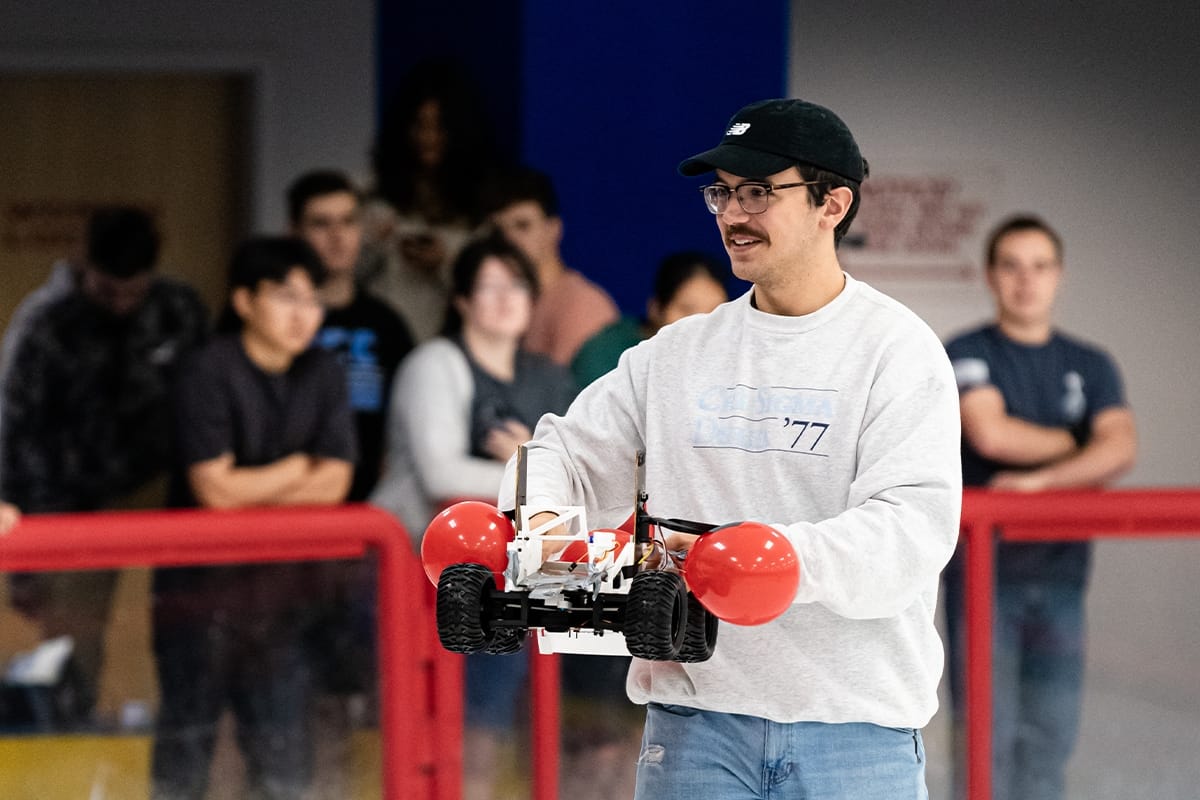

Pensacola Christian College students gathered around the Sports Center ice rink, forming an excited crowd to watch this year’s Engineering Design Competition. Five teams of students, ranging from freshmen to seniors, clustered around machines they had built—adjusting wires and doing final checks on the robots they had worked on for over six months. As wheels whirred and hummed, the teams got ready to compete.

“Team leaders volunteer to head up a team in the fall semester.”

The Engineering Design Competition has been held yearly since 1993, challenging generations of engineering students’ skills. Overseen by engineering faculty, the competition gives students of any classification the opportunity to lead and support a team. “Team leaders volunteer to head up a team in the fall semester,” shared Matthew Yonai (So., TX), a team leader. “The challenge for the year, rules, and budget for the competition are decided by the [student] leaders, Dr. [Joel] Porcher, and Dr. [Michael] Geary in the fall. In the spring, teams meet as often as they decide to work on their project.”

Challenged to Design

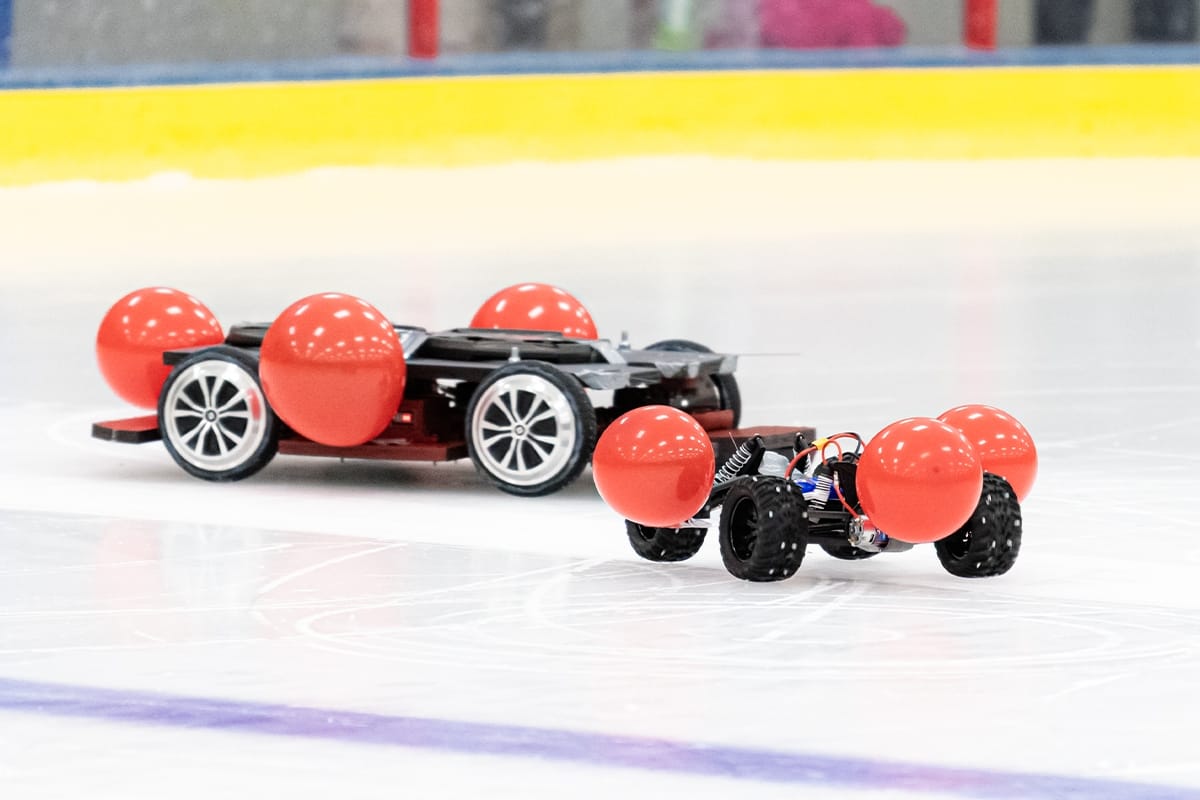

This year’s challenge was to design and build a remote-controlled (RC) robotic vehicle that could withstand a cold environment and traverse a low-friction surface. Machines faced a variety of obstacles: a race, a balloon dart battle, and a Hungry Hungry Hippos-styled challenge in which each team tried to carry the most Ping-Pong balls to a designated container.

The teams brainstormed robot designs that would give them an edge in the competition, and teams were responsible for coordinating their own budgets, building materials, and machine construction. Students also got a chance to put into practice what they have learned in class. “One thing that our team heavily relied on was 3D printing and 3D design, which is taught to engineers in Engineering Graphics,” Matthew said.

To make their robots effective, teams had to apply a collection of engineering techniques and principles. “The most challenging item we developed on our car would be our vacuum mechanism,” said Lexi Weitlich (Jr., PA). “[The vacuum] consisted of a 3D-printed hose nozzle that would collect the Ping-Pong balls and pass them up a vacuum-suctioned plastic tube,” she explained. The balls then went “into a painted milk jug with a flap in the back to discharge the balls into the final container.”

All the planning eventually culminated into many evenings on MacKenzie Building’s 5th floor, affectionately referred to as the “engineering floor.” Power tools growled, and students debated on final touches as they brought their masterpieces together, using the skills they’d learned in their classes. Knowing the difficulties the competition would present, teams collaborated and gathered ideas that would gain them an upper hand in the competition.

Teamwork in Action

Working with others gives students the opportunity to learn how to support a team in a workplace environment and simulates what collaborating with other engineers will be like professionally. “We learned that while brainstorming, every idea is valid, no matter how ridiculous. Only after brainstorming can you assess each idea and exercise reason,” said team leader Maksim Zakharov (Jr., CA).

“We learned that while brainstorming, every idea is valid, no matter how ridiculous.”

The process of concocting ideas and assembling the machines showed students that working together is better than working alone. Someone must hold a mechanism steady while someone inserts or adjusts wires. And sometimes a team member steps in to help where another team member is struggling. “It is great for learning how to work together as a team and bounce ideas off others,” said Andrew Royalty (Sr., TN).

Each student pulled from the foundational engineering skills they had gained from their classes as they formed the project. “Much of it was working as a team and practically applying the concepts we’ve been learning,” said Josiah Keating (Jr., MO). “Everyone has different strengths, and that really comes out when you’re working together. You pick up a lot of different techniques and skills and start understanding things that you hadn’t really thought of before.”

At every step of the competition, team members strove to create the best project they could, which meant everyone had to put in hard work. And when the teams met at the ice rink, their effort was put to the test.

Competition on Ice

On the ice rink, the teams proved their engineering prowess. In a series of games, robots collected Ping-Pong balls, raced across the ice, and charged each other, trying to pop balloons tied onto the cars. “Keep it simple” had been the building motto, and it proved valuable as each team’s RC vehicle demonstrated different aspects of efficiency in the games. Some teams’ vehicles sped through the race while others proved more adept at collecting Ping-Pong balls off the ice. Teams even got to show off their personal flair, with one vehicle sporting a 3D-printed dragon’s head. Overall, the competition bolstered the students’ confidence as future engineers. “I really enjoyed the competition, and it helped me to know whether I am in the right field or not,” said Levi Neinas (So., MI).

When wheels and motors hummed to a stop, the crowd of onlookers was delighted and thrilled with the event. Even the faculty overseeing this extracurricular class were impressed with this year’s Engineering Design Competition. “This was one of the best ones I’ve seen! And I’ve been here a long time,” said Dr. Porcher.

In chapel the following week, the vehicle nicknamed “Supreme,” headed by team leaders Jonathan Yonai (Sr., TX) and Matthew Yonai, was declared the winning robot. But all five teams had shown their ability in the event and gained valuable engineering experience. “There is nothing better than the satisfaction that comes with seeing your design successfully implemented,” Spencer Schmidt (Sr., NC) said. “This annual project has helped me make new friends and build leadership skills. The design competition is one of my favorite activities to be a part of at PCC.”