Most Saturday mornings, Eagle Field lies quietly, save a few eager ultimate Frisbee players. But on April 6, a small, excited crowd had gathered around the volleyball court at the end of the field. Five teams of students each surrounded a small machine. Some had treads and some had wheels, but all had an array of wires and whirring noises emanating from them. These Pensacola Christian College students were preparing to compete against each other in the annual Engineering Design Contest.

The challenge, discussed and agreed upon by the teams in the fall, was simple—tug o’ war and a drag race on the field. Each team had to design and build a remote-controlled robot that could withstand working against opposing forces without being too heavy to bog down in the sand, but also had enough power and resilience to compete in a race against the other robots.

“The challenge is an extracurricular activity for engineering students to have fun,” said Hunter Alexander (Fr., GA). “Engineering students were encouraged to attend a meeting and pick a team to join. The team leaders volunteered at the engineering seminar last semester.”

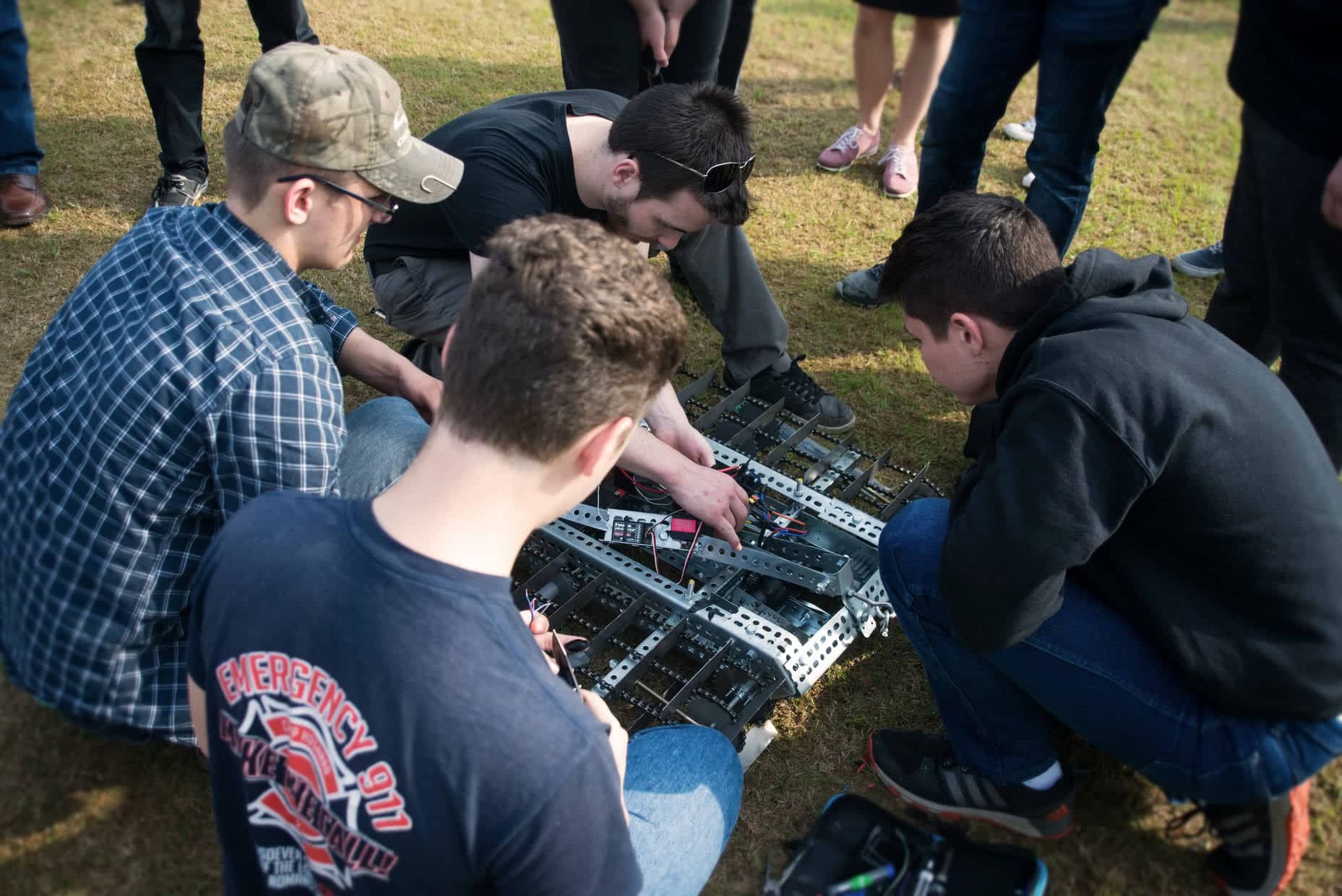

Over the course of the school year, each team worked through budgeting, resource management, and an ever-fluctuating number of team members as other events and responsibilities pulled some away during work nights. In the last weeks before the contest, evenings on the MacKenzie Building’s 5th floor became noisy from drills boring holes into aluminum sheets and plywood, exhausted chatter about how to connect certain pieces together, and belabored exclamations of “What could go wrong?”

Even though upperclassmen would have more experience for these contests, underclassmen like Hunter still had the opportunity to take up the responsibilities of leadership. “I am a freshman and a team leader, so this provides a fun project that is not based on how long you have been here, but allows for collaboration from all experience levels,” he said. “Being a team leader for something that is strictly extracurricular has aided me in learning how to coordinate with everyone’s schedules to have meetings.”

Through it all, each team worked hard to prepare for the Engineering Design Contest, but this contest doesn’t come easily for them. “Obviously our bigger goal is to win the competition, as is everyone else’s I’m sure, but at this point I would be very proud of my team if we had a working robot,” said team leader Rebekah Schueller (Sr., MN) a few days before the contest. Many years, there are a few teams whose robot designs don’t quite go as planned. “Having a working robot speaks a lot about your team and about your leader. It means you actually got the work done.”

At the volleyball field, that struggle was evident. Between RC controller problems, disconnecting treads, and temperamental wiring, only a couple of the remote-controlled vehicles were able to pull their own weight in the shifting sands of the volleyball court. During the race, only three of the five were able to charge forward through the dew-laden grass of Eagle Field, one of them traversing across the entire length of the field and back on its 3D-printed wheels.

“Initially, we knew we would be up against great competition being the only car not on tracks,” said Rusty Gipson (Sr., FL). “We used a simpler method of eight paddle wheels with eight independent motors. We designed our car with a high ground clearance which helped keep our car from bogging down in the sand. The competition was quite frightening!”

“Our vehicle used a track design that engineered to have the most ground connection at any time—far superior to tires. We have been able to explore different technologies including 3D printing, plasma cutting, and CNC milling,” said Hunter. “If we could redo, I would start ordering and assembling near the end of the fall semester instead of the week of the competition.”

The co-leaders of the winning team, James O’Connor (So., WA) and Rusty, had a goal for their team from the very beginning, inspired by last year’s winning team’s leader Silas Martin (Engineering: Electrical ’18). “The problem with a majority of vehicles in the design competition is overdesigning. The phrase ‘keep it simple’ was our team’s goal; [our] total design and assembly time was probably 10 percent of what other teams did,” said Rusty.

The team of contest winners, who are congratulated with the 2018–2019 Robert McLaughlin Memorial Engineering Design Award, will have their names engraved and displayed on a plaque on the 5th floor of the MacKenzie Building. Their accomplishment will be formally recognized during PCC’s 2019 Commencement Program.